Today staircases are a fairly relevant type of construction. It often happens that the area of the room does not always allow the installation of an ordinary one-flight staircase. But there is a way out - this is a staircase divided into two flights with a section of a spiral staircase between them.

This design is notable for both convenience and practicality, and it just looks stylish and modern.

Requirements for marching with a turn

The principle that any building structure in the house must meet is, first of all, safety. But the structure should also be comfortable to use. Passing stairs are one of the complex structures that must fully comply with these two principles. It is worth highlighting the main technical requirements that are characteristic of this particular type of construction.

- The main thing in the installation of winder stairs is proportions. The steps of the stairs must be located at exactly the same distance from each other throughout the entire flight of stairs. Usually, the distance between them starts from 100 mm and does not exceed 160 mm.

- Much attention is paid to the depth of the running step. Experts recommend an approximate distance of 100 mm in narrow areas. In the central part, the depth should be approximately 200 mm, and in wide areas, the step depth should not exceed 400 mm.

- For any staircase, it is imperative to provide quality fences. The run-in design is no exception to the rule. Typically, the height of stair railings ranges from 900 mm to 1200 mm.

- In winder structures, staircase width parameters should start from 900 mm. In principle, this parameter will depend on the design and individual characteristics of a particular staircase model. If necessary, this indicator can be increased.

- The range of 1900-2000 mm is set for the height of the free passage for a person. This is also an individual indicator that is set depending on a person's height. Taking the growth rate, you need to add 100 mm to it. This will be the optimal parameter for the passage height.

- The angle of inclination of the winder staircase should not exceed 45 degrees. This indicator is the maximum angle of inclination. The most comfortable and optimal angle is approximately 30 degrees.

- On average, the number of steps on winding stairs ranges from 15 to 18 pieces.

- The staircase must be able to withstand heavy weight, be stable and made of wear-resistant and durable materials.

- The approximate overhang of the step on such stairs should not exceed 5 mm.

Taking into account all the above technical requirements for a win-in staircase, the design will be safe and comfortable for its purpose. It is also worth noting the basic requirements of GOST for this type of staircase, namely:

- the depth of the winder should not exceed 40 cm;

- the minimum depth of the winder should be 10 cm;

- the depth of the center of the winder should be about 20 cm;

- the ceiling height above the stairs should not be less than two meters.

Types of structures

There are several main types of winders that are worth noting.

- Spiral staircases . This version of the winder is one of the most compact and aesthetic.

- L-shaped ladders are designed with a 90 degree turn. This option is also quite compact and takes up little space.

- U-shaped staircases are gate structures that are fully deployed 180 degrees.

- Curved staircases are the types of structures that have the smoothest turning lines.

- Monokosur stairs are simple in design. The structure of this structure is located on one support beam, that is, on one stringer, which is located in the middle of the steps.

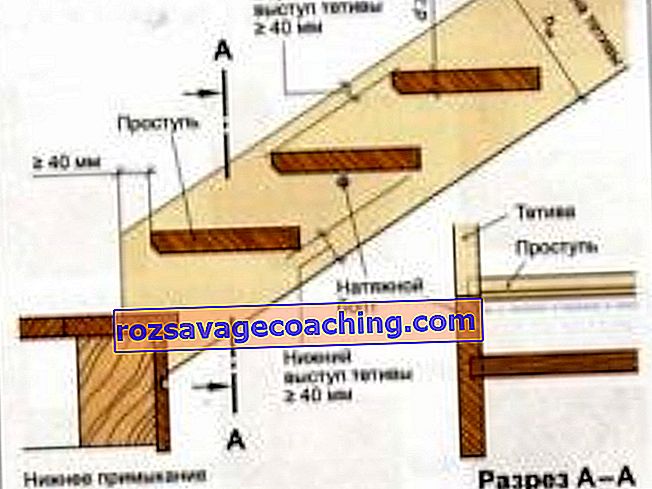

- Stairs on bowstrings are slightly different from the previous version, but are similar in design. In this case, the steps of the ladder are held by two wooden bowstrings. A wooden bowstring is usually additionally fastened on the opposite side with a metal rod for greater reliability.

Each of these types of construction has its own advantages, but they are all compact and save space in the living space. And also the location of the winder steps can be different. They can be located at the bottom or at the top of the staircase, as well as in the middle of the flight of stairs.

Advantages and disadvantages

Winder stairs have a number of advantages and disadvantages. Their positive features include the following:

- compactness and space saving. Quite often, residents are faced with the problem of placing an ordinary straight staircase to the second floor due to lack of space. The winder staircase does not require a large amount of space and fits into almost any room due to its small dimensions;

- appearance. The staircases look very stylish and modern. This adds aesthetics to the entire room;

- depending on the model of the winder staircase , much less materials may be required than for a full-fledged straight structure;

- such stairs have a smooth turn , which is very convenient when moving;

- variety of materials . Ladders of this type can be made from almost any material.

Among the minuses, the following aspects can be noted:

- due to its compactness, several people are unlikely to be able to disperse on the model under consideration;

- the design features of these structures are quite complex, for this reason it is difficult for them to make calculations.

Design and calculation

Considering that the winding staircase is a rather complicated structure due to its peculiarities, it is necessary to treat with special responsibility the preliminary drawing up of drawings and the exact conclusion of all calculations so that the staircase is comfortable and safe. The area of the room should be taken into account and the dimensions of the structure itself should be determined. After that, the following steps are performed:

- first you need to clearly determine the place where the structure will be located;

- extremely accurately measure the height from the floor to the second floor, as well as the width of the staircase opening

- Careful attention should be paid to the drawings based on measurements. Even the exact number of steps should be noted;

- it is necessary to decide what type of construction will be used, what type of building materials will be used.

Drawings and methods for calculating winders

Today, it is not at all necessary to draw up a plan and drawings of the future structure yourself. There are several convenient ways to do this and save you time and effort. For example, you can use design programs to design various structures. These are different applications and sites on which you can clearly calculate the amount of materials and other details.

You can also use ready-made drawings of winders. There are a huge number of them on the Internet today, among which you can choose the right one. But sometimes you come across incorrectly drawn up drawings that are not recommended to use.

And also when calculating the size of the stairs, you can resort to using online calculators. This is one of the most convenient ways to create a drawing of a winder structure. These programs allow you to make the necessary calculations and correct the set values. The programs are fully automated. They provide a rough drawing of the structure based on the set values.

Quite often, when calculating sizes, you have to use the proportion method. Most often it is used in the design of L-shaped and U-shaped stairs. In such cases, the following steps are taken:

- the middle of the march along which the line is drawn is marked on the drawing. Then, on this straight line, segments are marked that are equal to the width of the step;

- the border between straight and winder steps is marked;

- you need to clearly mark the middle of the turning platform of the stairs along which the segment is drawn;

- from the line that defines the middle of the turning part, it is necessary to set aside about half the size of the winders;

- from the estimated number of steps, the number of straight steps obtained from the drawing should be subtracted. At the same time, the tread depth is controlled in the middle sections of the march. If this indicator is less than the recommended one, then the number of steps should be reduced.

Materials and tools

To date, staircase structures are made from almost any material. They can be wooden, metal, glass and concrete. A combination of various materials is often used. Usually, the supporting frame of the stairs is made of metal, and the steps can be wooden or glass.

Of course, wood is the classic and most popular option. Such structures are both beautiful and lightweight compared to the same metal structures.

A number of major difficulties can be noted that arise during the installation of stairs.

- Particular attention should be paid to the quality of the material. Choosing low-quality products will make the stairs short-lived and unsafe. Therefore, you should familiarize yourself with all accompanying documents and visually inspect the material for damage and other defects.

- Considering that a winding staircase is a rather complex structure, it is worth remembering the error. It is necessary to have some carpentry tools to fit the structural parts.

It is important to carry out the installation of the stairs strictly at the same level. This will affect the evenness of the entire structure and its stability.

To carry out the installation of a wooden staircase, the following tools should be prepared in advance:

- electric drill;

- jigsaw (preferably electric);

- screwdriver;

- roulette;

- circular saw;

- self-tapping screws;

- iron corners;

- hammer;

- pencil.

Installation features

Despite the fact that it is not so easy to build a climbing staircase to the second floor, it is quite possible to do it yourself. To make a winding staircase with your own hands, you should follow the step-by-step instructions.

- First you need to start making kosour for the future stairs. For this, a template is made on the selected material, which has a triangular shape. In this case, school knowledge of geometry will be useful. The legs of this triangle should be strictly equal to the depth and height of the step. With the help of such a template, it will be very convenient to make markings and cut out the kosour. To cut it out, you should use a circular saw.

- It is necessary to hollow out a special groove in the post on which the stringer will be attached. The stringer must enter into this groove.

- Attention should be paid to the turning part of the stairs. In this case, the base for the turning steps is mounted on the wall.

- It is worth fixing the stringers at the top of the stairs. Metal corners are suitable for attaching them. It is necessary to fix them so that the stringers are strictly opposite each other. Then the future staircase will be flat.

- It is necessary to start cutting out the winders for the stairs. Specifically, for the run-in part, about three or four steps are needed. To cut them out, you need a wooden panel, which is divided into the required number of parts. To do this, you need to draw lines that go from one corner of the wood panel.

- The length of the steps is adjusted so that they are equal.

- You can do varnishing the steps before installing them, which will be much more convenient. Usually the varnish is applied to the steps in three layers.

- You can proceed to the complete assembly of the entire structure. For fastening the steps, grooves are also cut in the post. They should not be made too wide, otherwise the steps will not hold.

- You can additionally grease the run-in steps with glue and fix them with self-tapping screws. Ordinary steps are also fastened with self-tapping screws.

- It is necessary to proceed to the installation of the railing of the structure. There are several options for attaching them. You can simply screw them onto the steps with self-tapping screws.

And you can also use dowels, which are used more often and increase the reliability of fastening. For this, a hole is made in the steps and filled with glue. A dowel should be inserted into the hole.

- After installing the posts for the railings, they must be cut very accurately. To do this, a cord is fixed on the first and last pillar, which is pulled along all the posts. The level at which the posts are cut is marked along the stretched cord.

- After cutting, a handrail is attached to the posts, which can be fixed with self-tapping screws.

This instruction is suitable for making wooden stairs. But it is possible to highlight the stages of work on the installation of a concrete winder structure. This staircase has some characteristic features.

- First you need to decide on the exact number of winder steps, and then proceed to the manufacture of the formwork. When creating it, you need to provide for temporary strings. They will be needed in order to hold the load of concrete, because it is a rather heavy substance.

For the lower part of the formwork, thick and moisture-resistant plywood is suitable. And it is also desirable to make supports for the formwork.

- It is necessary to lay the reinforcement, which will form the shape of future steps.

- You can start mixing the concrete solution. For this, crushed stone, sand, cement are poured. The solution is mixed. After that, you need to add water to it and mix again for about 5 minutes. It is better to use a concrete mixer for these purposes.

- Finally, you can start pouring the stairs. You need to start from the bottom.

- After pouring, the steps must be carefully leveled. In the process of hardening, they need to be slightly moistened. Additional moisture will help prevent cracking.

Metal is often used in the manufacture of winder structures. They are made using profiles and sheet metal. But first you need to build the metal frame of the stairs. Prior to this, segments of the required length are prepared and welded to each other in the shape of the future structure. Using the above instructions, it is quite possible to make the winder structure yourself. This does not require particularly deep knowledge and skills in construction, but it will take a fair amount of time and effort.

If there is no confidence in the independent manufacture or installation of the stairs, then it is wiser to seek help from professionals.

Modern manufacturers today make a huge number of different models of winder stairs, among which you can choose any one depending on individual preferences. Do not think that a purchased ladder will be very expensive. There are stairs of completely different price categories, and many cheap stairs are not inferior in quality to expensive structures.

The materials used in the manufacture of stairs by large construction firms are incredibly wide and varied. In the current market, you can even find glass stairs that have an incredibly aesthetic appearance.

Purchased structures are very easy to assemble, so they can be installed and installed without outside help.

So, winder stairs today are one of the most practical and convenient options for staircase designs. They have a lot of positive sides, although you shouldn't forget about the disadvantages. Many are attracted by the opportunity to create an original staircase on their own, without professional skills and abilities. The main thing is to correctly design and calculate, as well as purchase all the necessary materials and tools.

For information on how to make a wooden staircase with your own hands, see the next video.