The design and installation of wooden stairs is in demand as many people decide to build a two-story house. The staircase is a key part of the interior, so attention should be paid not only to its functionality, but also to its decorative characteristics.

Features of wood structures

Wood is the simplest and most environmentally friendly material. No special skills are required to work with it. It is possible to make stairs from wood to the second floor, located inside the house, as well as the porch in front of the entrance to a private house.

Wooden products that can be assembled like "Lego" have the following advantages:

- affordable price category;

- the prevalence of the material;

- ease of handling.

Most often, stairs are made of pine. Such wood is soft, so beginners like to work with it. The disadvantage is the soft texture, due to which the product begins to darken and creak. For this reason, experts recommend treating wood with special substances in order to exclude early repairs.

People who want to build a more beautiful and reliable staircase in their home choose expensive types of wood. These include massive oak, larch. The material has a unique texture and high wear resistance. Among the disadvantages is the high cost.

To save space, you can use the swivel design option. Depending on the available space, the product can be rotated 90 or 180 degrees.

The features of wooden stairs include the ability to recover. The restoration allows you to restore the original appearance and shape of the product. With the help of these manipulations, you can increase the service life of structures. The restoration has three key tasks:

- restoration of the original appearance, surface quality, finish, color scheme, along with functional and operational characteristics;

- treatment of the product with antifungal and antiseptic agents, providing protection against moisture, fire and UV rays;

- partial or complete reconstruction of the staircase, if necessary.

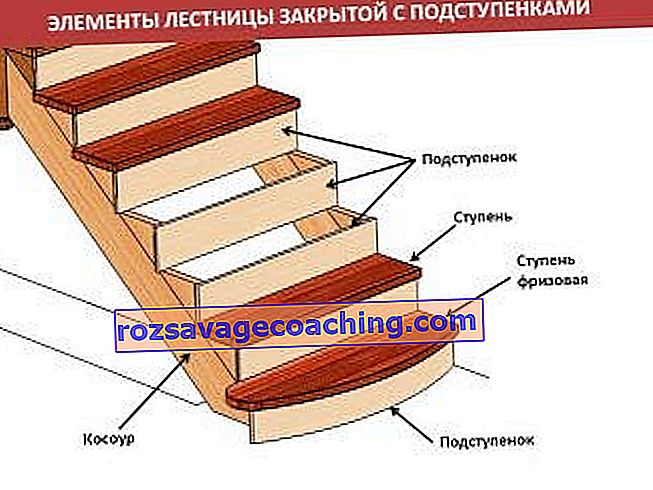

Essential elements

In wooden stairs, there are details with which the whole structure is assembled. These elements are considered key, so you should get acquainted with them before drawing up drawings or buying a ready-made version.

- Kosour is a load-bearing beam, due to which the steps and risers are supported. The entire load is carried out on this element.

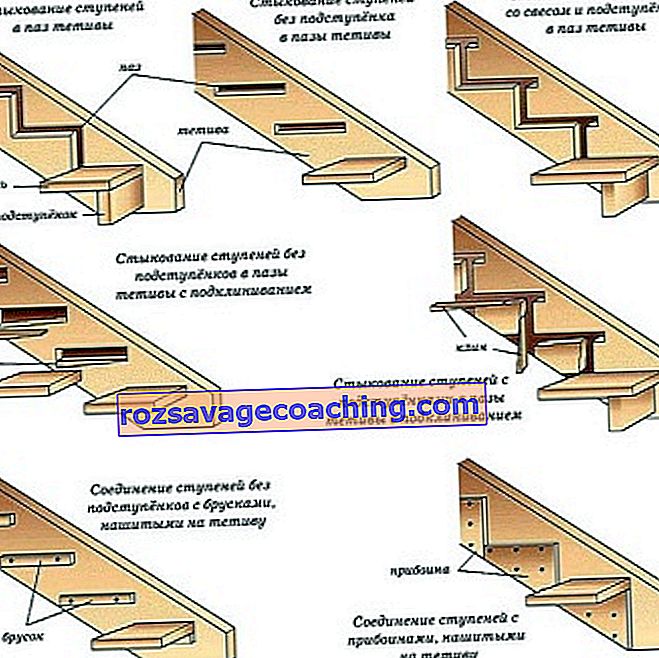

- Bowstring - this component is responsible for the supporting mechanism. It contains recesses into which the end of the steps is inserted. The product can be used on one side, when the ladder is leaning against the wall, or on both sides, when the flight is located between two walls. The bowstring is not as popular as the stringer because it does not target low loads.

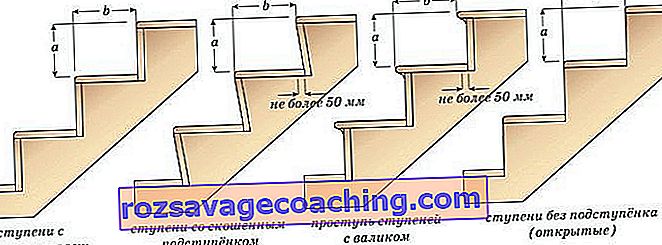

- The steps are a wooden beam with a horizontal tread and a vertical riser. The person steps on the tread with their feet, and the second element is responsible for fencing the tread and supporting the entire part. Some people choose stairs without risers. In this case, the structure will not have sufficient strength and reliability. The steps can have a rectangular shape; it is also common to manufacture radius elements for an attractive approach to the stairs, turning, to replace dividing platforms with winders. In this case, the first steps will have a non-standard shape.

- The stair railings are wooden balusters with handrails. The shape and dimensions of such products may vary. As a rule, the production of products is carried out to order according to the wishes of the owner of the apartment. Carved options look attractive.

- Stairwells are structural details that act as a connecting component for adjacent staircases. The element consists of steps that are fixed on a stringer or bowstring. Has a fence, the height of which must be at least 900 mm.

- If there is more than one flight in the staircase, there must be a support pillar or pillars at turns in its structure .

Views and styles

Interfloor wooden stairs are considered the most popular designs for home furnishing. Using wood, you can create a simple economy class staircase or make a chic piece of art that will attract the attention of guests. There are two types of wooden stairs that are most often installed in a home: spiral and marching.

Screw

These stairs attract the attention of many users with their compactness and interesting appearance. Such designs fit perfectly into the design of Provence-style rooms.

When creating a spiral staircase, some features should be taken into account.

- For a comfortable and safe use of stairs, the central width of the steps should be at least 20 cm.The widest section should not exceed 40 cm.

- The structure can be located near the load-bearing wall or in the center of the room. The product takes up little space, but due to its complex design it is difficult to go down it.

- Typically, these items are considered optional. They are ideal for small openings. However, there are models with a diameter of more than 3 meters.

- The smaller the opening, the steeper the climb near the stairs.

Marching

Marching structures are the most common type of stairs, which are often installed in country houses. Marching stairs, depending on the type of construction, are of the following types:

- on kosoura;

- on bowstrings.

In stringer products, the steps are arranged according to the "saddle" type. They are mounted on top of a stringer beam, risers are fixed at the end. The beam is characterized by a sawtooth shape. Such stairs are not in wide demand, unlike bowstrings, but they look attractive in the interior.

This option would be appropriate in country style.

Bowstrings are inclined type bearing beams. They are located along the entire length of the flight and act as the base of the stairs. Most large ladders are bowstrings. The bowstring covers the end element of the march. The steps are fastened into grooves that are located inside the support beam. The beams must be more than 6 cm thick.

Marching designs are more common. It is convenient to climb along them, since the products take into account the biomechanics of movement. The staircase is suitable for spacious rooms. The dimensions of the structure and the required dimensions of the free area can be calculated using the following actions:

- measuring the height of the wall next to which the stairs will run;

- calculation of floor length;

- then you need to draw a right-angled triangle, in which the floor with the wall acts as a leg, and the structure itself acts as the hypotenuse;

- the optimal staircase angle is 45 degrees.

Marching structures are considered more reliable compared to screw structures. Despite the fact that the staircase requires more space, it is more often installed in the house. Such products can have several flights, however, one- and two-flight designs are common for a private house. Such interior details are diverse.

To make the staircase take up less space, a pivoting two-flight structure is used.

Swivel

The turn of the staircase can be positioned at an angle of 90 to 180 degrees. If space permits, the staircase can have a curved structure. When planning the location of such a staircase, you should ensure that households enter it comfortably.

Smooth turns in a curved structure are achieved by installing rotary steps. Such elements are often used in two-march structures, replacing the platforms between them.

Standard single flight staircase

A prefabricated staircase with one flight is the simplest design. The flight of stairs can be located near the wall or in the center of the room. The landing of the flight of stairs should be used rationally. Many people build partitions on this site, behind which utility rooms are located. These stairs are considered the most durable if they are located next to the walls.

Such stairs are usually in demand in large rooms, as the products show spaciousness. In small country houses, such designs will not look good, as they "eat up" all the useful space.

Single-flight curved staircase

These are large structures, as they have smooth curves and widened steps on the outer sides. Externally, the products are similar to screw. The staircase is distinguished by respectability and can decorate any spacious hall.

If the location of the stairs was taken into account when planning the house, a curved structure with one flight should be chosen to climb to the second level. The product is compact and attractive, convenient for movement. A storage room can be arranged under the stairs on the ground floor.

One flight, located in a narrow opening, can bend almost 180 degrees.

Single-flight with lower rotary steps

Such stairs are suitable for rooms that need to emphasize the style, or the peculiarity of the room does not allow the installation of another structure. For example, when there is a window on the site for the installation of the stairs, which you do not want to close with a two-flight structure.

The required direction is set by the lower rotary steps. Thanks to the smooth rotation of the lower steps and the smoothness of the handrails with railings, the staircase can turn into a true work of art and become a decoration of the room, efficiently coping with the tasks assigned to it.

Standard structures with two flights

The structure, which has two flights and a turning platform between them, is convenient. It lies in the fact that the stairs can be located above the entrance to the house, thus saving free space.

The design is compact, the space under it can be used as a storage room. The product is reliable and can be combined with any interior if you make the right choice of color and shape.

L-shaped staircase with two flights

Such structures also have two flights, but its placement allows you to save free space in the room. The structure is placed in a rectangular span on the sides of perpendicular walls. The space under the stairs can be used to position furniture or a doorway.

Both marches are at right angles. It is convenient to use such a staircase, it is compact and can fit into any room interior.

U-shaped staircase with two flights and turning steps, upper platform

Such structures are installed in luxurious country houses with a spacious hall. The staircase is massive, so it is not suitable for a country house. Most people call such items elements of the palace interior.

Designs with three flights

Three-flight staircases are relevant in homes where you want to save free space. High ceilings are required to make the lift angle comfortable. If there is no overlap between floors, the quadrature of the second level will be significantly reduced. This version of the staircase is suitable for mansions with spacious rooms.

Correct location

Interfloor staircases are used as a link between the floors of a country house or apartment. The installed products must be durable, safe and comfortable. The staircase is a key link in the interior that cannot be masked or hidden.

The question of the location and type of construction of the stairs in the dwelling should be thought out at the initial stages of design , since the layout of the house depends on this structure. Given the characteristics of the element, it is necessary to place the hall and entrances to other rooms.

The area in front of the stairs and next to it, the comfortable location of the staircase "start" and "finish", the lighting layout are the key details of the comfort and harmony of the interior. The security issue is entirely related to the convenience issue.

It is best to place the stairs near the geometric center of the dwelling in order to shorten the length of communications. You will need to take care of a convenient approach to the stairs and surround it with a free area so that a couple of people can pass by on it.

Stairs are often installed in hallways and hallways. This arrangement guarantees the autonomy of the rooms and makes it possible to enter the second floor directly from the entrance. Some people place structures in the living room, using them to decorate the room. The hall on the second floor can be turned into a gallery, open to a living room or a corridor.

Spiral staircases with a gallery are often located in the living room. It is not very easy to lift and requires limited use. For example, to access the mezzanine.

The question of the location of the stairs should be taken responsibly, since further changes are accompanied by significant difficulties associated with the reconstruction of the entire house.

Load calculation

After the place for the stairs has been chosen, it is necessary to do precise calculations, draw drawings and apply all dimensions to them. Compliance with the design of GOST is a mandatory requirement when making calculations. These standards define all the characteristics that a safe and durable structure must have.

The standard describes every detail that must meet the stated requirements. In the calculations, it is necessary to take into account the width, the number of steps, the angle of inclination, the width of the passage and other parameters.

In GOST there are several documents that describe different types of staircase structures. For marching structures, a standard 23120-78 has been created, the installation of fences is carried out in accordance with GOST 25772-83.

Ladder height

To calculate this value, you will need to measure the distance between the floor surface of the first and second levels. If the ceiling height on the first floor is 2700 mm with an interfloor floor thickness of 300 mm, the staircase is calculated according to the universal formula: H = 2700 + 300 = 3000 mm.

Riser height

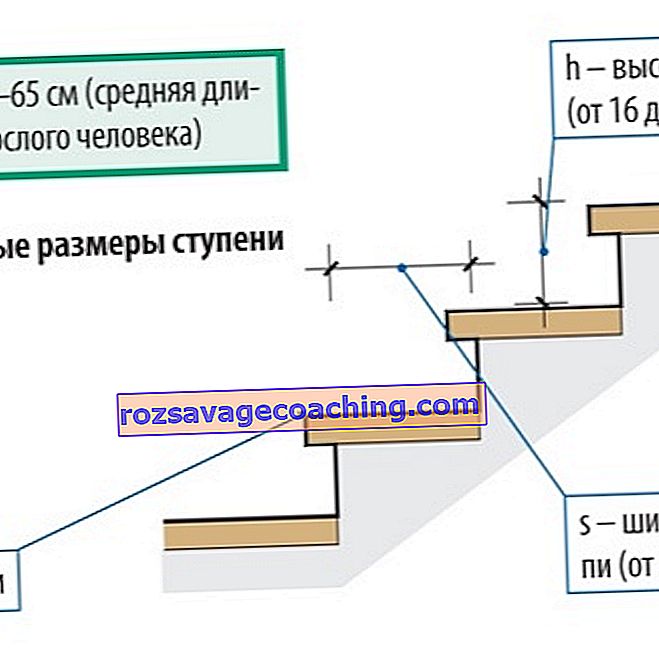

The approximate height of the risers is calculated based on the person's step. This parameter can be from 150 to 200 mm. If you make the height of the steps too high, then you can stumble or even fall when climbing.

This height is dependent on the total height and the planned number of steps. To make a correct calculation, you should use the average height of the risers based on standards - this is about 175 mm.

Number of steps

Having calculated the height of the staircase itself and the riser, you can calculate the total number of steps. To do this, you need to divide the height of the stairs by the height of the riser. The resulting value will show the total number of steps. The resulting amount must be rounded to the nearest whole number.

Step width

To exclude injuries sustained when moving up the stairs, the width of the steps should be calculated. According to many years of practice, it was found that this indicator should not be less than 220 mm and wider than 400 mm.

A special formula has been developed according to which the required width can be calculated. In calculations, use the "k" value, which is the average step width. The size ranges from 600 to 640 mm.

The formula is calculated using the formula b = k - 2a, where:

- a is the height of the riser;

- b is the width of the step;

- k is the stride length (average).

Stair width

This indicator depends on the area that is reserved for the staircase structure and the tastes of the owner of the home. For this reason, the width can be anything. However, safety rules should be followed, according to which the specified parameters should not interfere with the evacuation of people in an emergency. The span width, based on this rule, must be more than 800 mm.

In order for households to calmly move around the structure, as well as to be able to move furniture, the width should be arranged from 1000 to 1500 mm.

To simplify calculations, experts recommend starting from the width of the march in relation to the width of the steps.

Ladder length

To calculate the length of the structure, you will need to know the length and width of the steps and multiply these values. Based on the obtained value, you can choose the number of marches. With a length of more than five meters, the construction of two marches will be required.

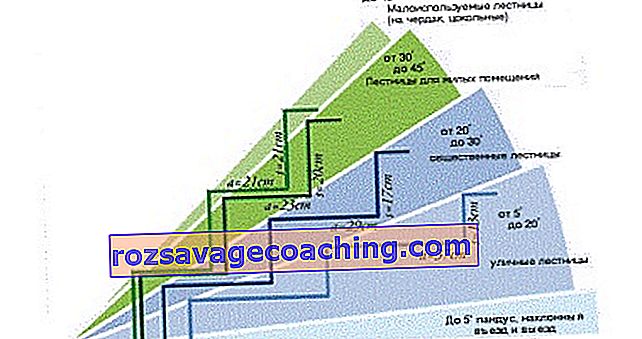

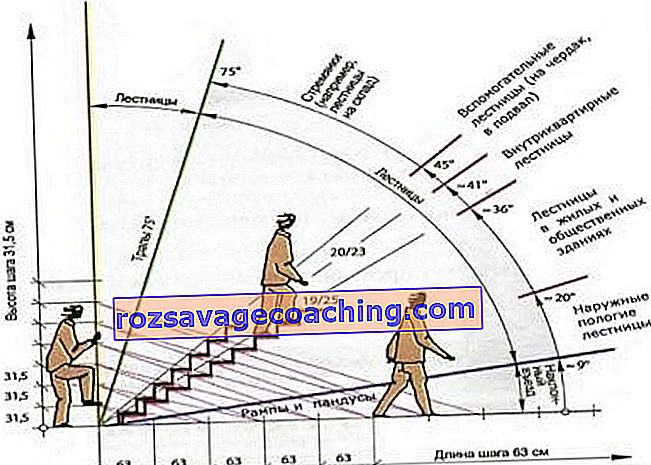

The slope of the structure and the parameters of the opening

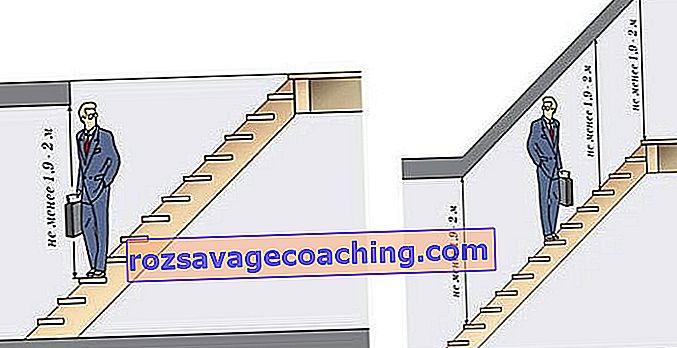

When building a staircase, remember about the ceiling opening, the size of which must also be calculated. If you do not take care of this issue in advance, when climbing to the second level, household members will need to bend over so as not to hit their head. The angle of inclination affects the comfort of use.

The optimum slope is between 23 and 36 degrees. However, some users cannot equip the structure at such an angle due to the small size of the room. The steeper the slope, the less area required for the stairs.

If the structure can only be installed at an angle of 45 degrees, it will not require a large area, but such a ladder is considered an accessory.

To save space, many users choose folding ladders. If the stairs are rarely used, this option is considered optimal.

If it is possible to install a structure on a 1.5 m2 site, a screw structure is suitable, which does not require a lot of space. In case of insufficient squaring, the creation of a spiral staircase will be required.

The size of the ceiling opening depends on the installation angle of the staircase. A small hatch is required for access and folding ladders. For a more convenient slope, you need to equip a large opening, since the distance at any point, throughout the entire ascent between the ceiling and the steps, should not be less than 1.95 meters.

The ceiling opening must be high enough so that the person does not hit his head on it. Calculations must be made in such a way that a tall household member can move freely along the flight of stairs. To do this, you will need to measure several indicators during the marking of a single-flight staircase located near the wall.

- The angle on the wall is determined under which the installation of the structure is carried out.

- Marking points on the floor and on the ceiling, connect them with a solid line. In the future, supports for the steps will be fixed along it.

- On the designated segment, a place is determined where the distance between the floor and the ceiling will be two meters.

- From this point, you need to draw a line to the joints between the wall and the ceiling. It will designate one border along which the opening will be created.

- A line is drawn at an angle of 90 degrees to the joint. The length of the line is identical to the width of the stairs.

- The second half of the ceiling opening is created in the same way.

A similar rectangle is drawn on the floor surface, which should be located exactly under the ceiling opening. As a result, the size of the opening will be shown on the ceiling, with which you can safely navigate the stairs. Then you need to cut an opening in the ceiling on the ceiling.

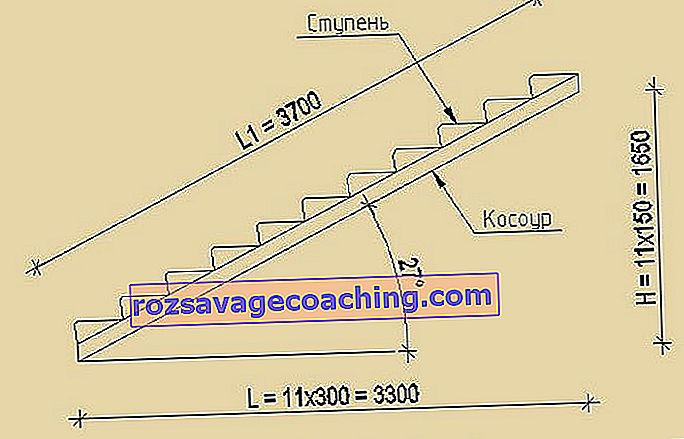

Stringer length

To determine this indicator, you will need to recall the Pythagorean theorem, with which you can determine the relationship between the sides of a right-angled triangle. For this, the formula L² = F² + H² is used, it follows that L = √ (F² + H²), where:

- L is the length of the stringer;

- F is the length of the ladder;

- H is the height of the stairs.

Materials and accessories

After the calculations have been made, you can start purchasing the basic material and accessories.

- First of all, it is a board. You will need material for a stringer or bowstring, the width of which will be about 250 mm, thickness 50 mm. The length is calculated using the formulas. And you will also need boards for steps and risers.

- Balusters can be bought ready-made or made by hand. Some users buy wood, which is already cut according to the calculations made.

- Nails.

- Self-tapping screws.

- Metal corners for reinforcement.

- For the fence, you can use wood or use forged parts. With the help of artistic forging, exclusive beautiful staircases are created, which become the central link of the entire interior.

After the manufacture of the staircase, finishing will be required, which consists in priming, painting and varnishing products. To do this, you will need to purchase the appropriate materials and select the desired color.

Manufacturing

After carrying out the calculations and completing the drawings, you can start the manufacturing process. Wooden stairs can be made by hand. To do this, you will need to follow a certain sequence of actions.

Step-by-step guide to making a ladder:

- markings are applied to the bowstrings or kosour, for this you can use a right-angled triangle or a special corner on which the legs will be marked (they will mean the width of the tread and the height of the riser);

- the length of steps and risers is measured along with other details, the sawing of which will be done by hand;

- sawing should be done with an electric saw;

- then you need to process all the prepared components with sandpaper;

- if the ceiling opening is not ready, it should be created by dismantling.

This instruction shows the sequence of work with which you can independently make a staircase structure. Each stage should be considered in more detail to exclude possible errors.

Bowstring or stringers

On the cut, which is prepared for creating these parts, you will need to mark the required length and cut off the excess parts. Then "combs" are marked according to the given calculations. For these purposes, you need to use a square or a long ruler. The strip of the board that remains intact must be greater than the total width of the board.

Creation of markings on the stringer for cutting the "comb"

The marking of the stringers is made taking into account the slope angle under which the structure will be installed. Base for the first step, the bottom cut for installation on a concrete base must be aligned with the slope line marked on the walls. The steps should be horizontal. It is not allowed to "roll over" outward or inward.

To eliminate errors, experts recommend using a ready-made template. Taking into account the specified parameters, you should make a markup and cut out the entire comb. To simplify your work, you can create a template based on the first step.

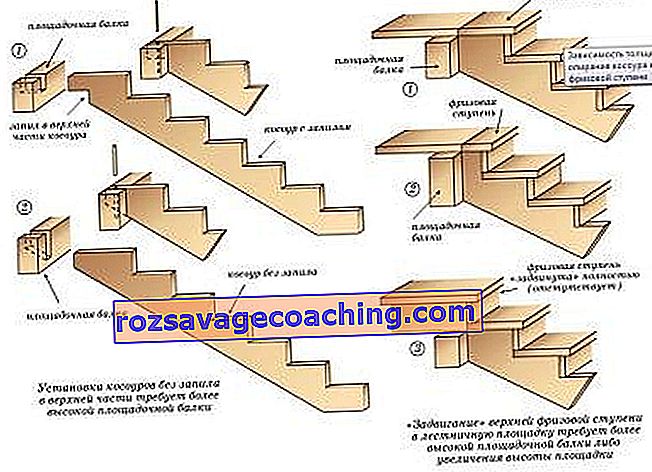

The next step is to fix the limiting stop bar along the line along which the staircase will begin. To mount a stringer to a beam, you can resort to one of two methods:

- create saws in the form of grooves directly to the beam;

- make cuts in the form of grooves on the stringer itself.

Fixing the stringer to the crossbeam

The finished stringers are mounted on a support bar on the floor surface, after which they are tightly pressed and attached to the wall and ceiling opening. Hanging stringer is installed on the floor and in the opening to the support bar. To provide the structure with sufficient rigidity, 3-4 stringers are required. In the ceiling opening, they are also connected using a reliable bar.

The bars on which the base of the structure rests must be firmly fixed to the floor and ceiling opening.

Make sure that the parts are perfectly aligned with each other. Compliance with this rule guarantees that there is no side slope of the steps.

Installation of risers and steps

Installation of risers is carried out on fixed stringers. The length of the risers must be identical to the width of the staircase. After fixing them, you can start installing the milled steps. The length of the board should exceed the width of the distance between the outermost stringers by 10-20 mm. The width may be 20-30 mm larger than the projection of the dies.

The treads are fixed with self-tapping screws in such a way that the head of the fastener is completely inside the wood.

Installation of support pillars and balusters

Support poles with balusters must be installed after accurate marking and adjustment. Along the edges of the steps, areas should be marked on which ready-made balusters with pillars will be placed. The hole in the steps should be at a distance that is equal to half the width of the base of the baluster so that the edge of the part is identical to the side cuts on the steps.

Then holes should be created on the steps. The finished dowels are glued into the equipped holes. The dowel must be on top of the step at a distance of 10-15 mm. By its diameter, holes should be drilled at the base of the baluster and the pillar. Pillars are placed at the beginning and at the end of the march.

Initially, you only need to put the upper pillars. The bottom parts are put last.

Having mounted a pair of balusters on the dowels, you should measure the angle of the upper surface by fitting the handrails. Having decided on the required length, you will need to mark and cut off the excess section from all parts.

The base of the balusters with holes for the dowels must be coated with glue, after which they are pushed onto the protruding dowels. The balusters should be placed vertically and pressed against the steps.

Next comes the preparation and assembly of the railings. You will need to cut the edges and drill holes on them to connect to the support posts. When the glue is completely dry under the baluster, you can proceed with the installation. The top cut hole should fit over the top posts of the dowel.

Next, the railing must be placed on the balusters, which are smeared with glue. Due to the milled grooves, the balusters are securely fixed in the desired position. To provide additional reliability, you will need to screw the balusters to the railing from below using thin self-tapping screws.

The last step is the installation of the support pillar, which is connected to the lower railing sections. The connection is made by gluing the dowel.

How to install?

The staircase assembly process begins with the installation of the supporting parts. Anchoring at the top and bottom points should be done with an angle bracket, threaded connection or anchor. Before finally fixing the supporting structure, it is recommended to check the coincidence of the horizons. For this, a level should be applied, which is placed on the horizontal place of fixing future treads. If the kosour was cut with one piece, the correct fixation is ensured.

Installation involves the use of a building level, which must be kept with you at all times.

Installation of a ladder from logs

To create a ladder structure, you will need to cut the logs in half. The resulting blanks will be used to create steps and bearing parts. After the front side of the product has been processed with a plane and sandpaper, the markings have been applied, you can proceed to the installation process. Steps and fasteners will be fixed on the inside. It is best to use steel corners fixed with anchors for these purposes.

Then the supporting structure should be installed, fixing it to the ceiling and to the floor. According to the markings, the bars should be attached to the string with self-tapping screws.

Before attaching, you need to check each horizon with a building level. Thus, each stage should be checked.

Next, holes are drilled through the bowstring at the end of the steps, eliminating the displacement of parts. The anchor must be tightened to the stop. To fix each step, 4 anchors are required. To provide additional reliability, silicone sealant must be added to the inside of the holes.

To install such a staircase, you will need threaded connections with the equipment of hidden "windows" in the steps. They are needed for the tightening components.

Finishing

After installing the staircase, you will need to finish it. It consists in painting or varnishing the element.

Coloring consists of three stages:

- preparatory work;

- staining;

- applying a varnish layer.

First of all, you need to start preparing every detail of the staircase for the painting process. This will require puttying and sanding.

For the putty, special mixtures are required, aimed at working with wood. The use of materials intended to work with other coatings is not allowed.

After the putty is dry, you can start sanding the surface. The work is divided into two parts:

- rough, superficial processing, after which you should wait two days;

- second grinding.

After sanding, the wood gets an even and smooth surface. Now you should deal with the application of the paint material. Before painting, apply a primer coat. The primer is selected to match the paint. There are white, black and even blue undercoats. It is recommended to cover the stairs with alkyd or urethane paint. They are best suited for wooden stairs.

Designers are advised to pay attention to light colors.

Some users use wood stain for coloring. This tool is able to emphasize the uniqueness of the wood pattern, so the staircase takes on an attractive look. Natural drawings are always in demand, so do not hide the beauty under a layer of paint.

The stain is selected together with the varnish. You need to choose high-quality formulations. Stain is not only a coloring agent, but also fully protects wood from the effects of the external environment.

When the paint is dry, you can start applying the varnish. Matte varnishes are popular. It is recommended to apply the product in three stages. Each layer is applied after the previous one has dried. If bubbles appear on the surface, they must be sanded.

Wooden stairs can be finished with laminate. This will require taking into account the features of this material.

- A laminate of at least class 31 is suitable for work.

- When buying material, remember that each step should be equipped with a solid board.

- Facing work is performed with solid material, so you need to make a competent calculation of the product.

- Often the steps can have different widths, so calculations should be made based on the widest part. Then you need to count the number of steps. The resulting amount of material is required only for treads.

- Then you need to multiply the height of the risers by the number of steps. If the staircase is facing, you should remember that there is a landing.

- It is recommended to place a cork or polyethylene backing under each step before finishing. This will create high-quality surface cushioning, as well as reduce the noise level when moving up the stairs.

- To connect multilevel surfaces, there are special profiles on sale. With their help, you can produce a beautiful decor of joints. And also the profile is responsible for load distribution and uniformity of material abrasion.

- To finish the laminate, you will need tools. The most convenient way to cut the board is with an electric jigsaw. If this tool is not available, you can use a hacksaw or circular saw.

Oil can be used to decorate wooden stairs. The tool provides reliable protection to wood, and also preserves its original appearance.

Interesting examples

Designers offer limitless ideas for creating wooden stairs. Structures can be made in any color scheme and style, depending on the preferences of the home owner and his capabilities.

Classic

This is a versatile staircase format that is ideal for elegant interiors. Such staircase structures are usually supplemented with radial handrails, balustrades, balusters and other decorative details.

Victorian style

These stairs are perfect for bohemian interiors. The structures are made of solid oak, beveled, carved and edged. Many designers offer decoration of structures with balls, blossoming roses. The use of cone-shaped or cube-shaped balusters, handrails with fillets is actual.

Country

These are massive, practical and comfortable products that are not characterized by pomp. Ladders are made of timber hewn with an ax. As a decoration, you can use a simple decor in the form of wooden figures. Structures should have a casual look and feel of a stand-alone product.

Neoclassic

These stairs have an antique appearance that attracts the attention of all guests. The structures are often sinuous and white in color, equipped with stepped podiums, short roller shutters and cone-shaped balusters.

Modern

These are elegant spiral structures, which are distinguished by strict forms, complemented by forging and floral ornaments.

Art Deco

Constructions made in this style have thin and graceful steps, between which there is free space. Due to this feature, the effect of "floating in space" is created. The stairs are characterized by the severity of lines and ethnic patterns.

For information on how to design and install wooden stairs in a country house, see the following video: