When soldering contacts, the main task of a soldering iron is to melt the solder and apply it to the desired places. Of course, for this, the soldering iron must be heated to a certain temperature. Moreover, for the processing of different metals, this indicator can differ significantly. Too high or, conversely, low temperature of the tip of the device will affect the quality of the work performed.

How many degrees can it heat up?

There is a so-called optimal temperature range at which the soldering of the required surfaces will be as fast and high-quality as possible. But there is one important feature that every specialist in this business should know: the temperature at the tip of the soldering iron tip must be higher than the melting temperature of the metals being processed.

In this case, the solder should generally melt in a few seconds.

An excessively high temperature will turn the solder into a mass of a certain consistency, which will be very problematic to work with. The optimum is considered to range from 245 to 300 C ° . If the soldering iron is overheated, then this figure can increase significantly. For the convenience of working in modern devices, the required temperature can be set independently.

What temperature should it be?

As already mentioned, the most comfortable temperature range for work is considered to be from 245 to 300 ° C. But the point is that all soldering irons are designed for processing various metals. For example, to solder some metals, the soldering iron needs to warm up to 600 degrees. Moreover, their power can also vary. The optimal range is from 25 to 40-60 watts. Soldering irons with a minimum power of 8 W and a maximum power of 200 W are much less common. As a rule, soldering irons used in production on an industrial scale have high. Devices for home use do not have significant power. But the working power of an ordinary household appliance can reach 100 watts.

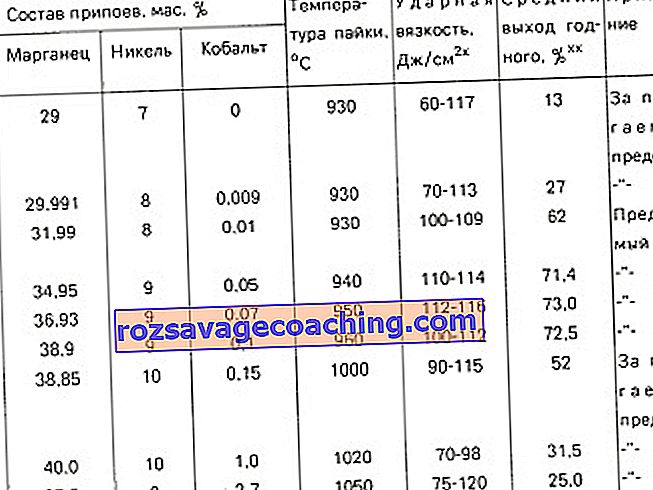

Solder

The working temperature of the soldering iron for each process is determined individually. In the process of soldering contacts of the same type, it is permissible to set the same temperature. But at the same time, the composition of the solder must be identical.

In cases where it is necessary to use a different type of solder, sometimes you even have to change the soldering iron.

Depending on the type of solder, the temperature of the tip of the device should be as follows:

- Wood's alloy - 75;

- Rose alloy - 95;

- PSRZI - approximately 145-146;

- POI 30 - 175;

- POS 61 - 195-197;

- O2 - 237;

- PSR - 240;

- PSR 2 - 248;

- PSR 1.5 - 285;

- POS 10 - 305.

All temperatures shown are in ° C.

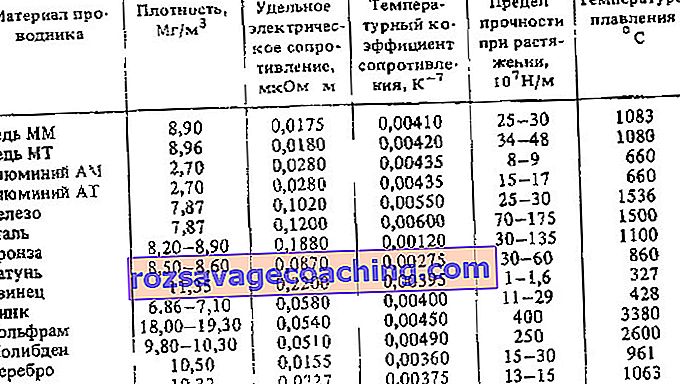

Depending on the material

The temperature of the tip is a very important indicator that must be changed not only due to the composition of the solder, but also depending on the type of surface being treated. Here it is important to know not only the temperature of the soldering iron, but also the temperature at which the metal being processed melts.

The melting point of the most common metals is different and looks like this:

- cast iron - 1200;

- steel - 1400;

- silver - 961.9;

- lead - 327.4;

- tin - 231.9;

- copper - 1084.5;

- gold - 1063;

- iron - 1539;

- aluminum - 660.4.

Temperature readings, as in the previous case, are measured in degrees Celsius. When working, it is important to compare the technical characteristics of the device with the capabilities of the metal being processed.

How to get the right one?

The temperature of a soldering iron tip with a power of 100 watts has some limitations. So, at maximum heating, it is impossible to exceed the maximum threshold, but it is also unacceptable to lower it so that it is constantly at the same level. To select the right temperature, you need to focus on the power of the device. For quite a long time this technique has been the most popular. Indeed, in Soviet soldering irons, it was impossible to find out the temperature in another way. But this method also had a significant drawback, since several types of soldering irons had to be bought for processing different surfaces.

More modern models are equipped with a built-in temperature controller . Likewise, knobs are sold separately. This device can be installed on almost any model. It easily solves the problem of lowering the temperature. The bottom line is as follows - if the soldering iron has a power of 60 watts, then when you turn the knob by half, the temperature of the tip will decrease to the values of a soldering iron with a power of 30 watts. Soldering with such a device is much easier.

If possible, then it is better to buy not the regulator itself, but those models of soldering irons in which this device is already installed.

When processing microcircuits with such a soldering iron, you can adjust the temperature up to 1 ° C. At cost, such devices differ significantly from ordinary ones. But they make the work of the master several times easier.

How to find out?

In models with a built-in sensor, temperature readings are shown on a special display . In order to find out the heating temperature of the tip on a conventional soldering iron, you must use special measuring instruments. There are so-called soldering iron thermometers. The basis of this device is a thermocouple that determines the heating indicators. In this case, the error can vary by several degrees up or down.

Another way to measure heating temperature is to use a multimeter. This is a very common technique that allows you to accurately and quickly find out the temperature conditions of devices of different models.

For work at home, approximate temperature indicators are very often selected, since this is enough. But with professional soldering, for example, when working with microcircuits, you need to select the temperature as accurately as possible. Missing this point can ruin the whole work.

See below for soldering temperature.